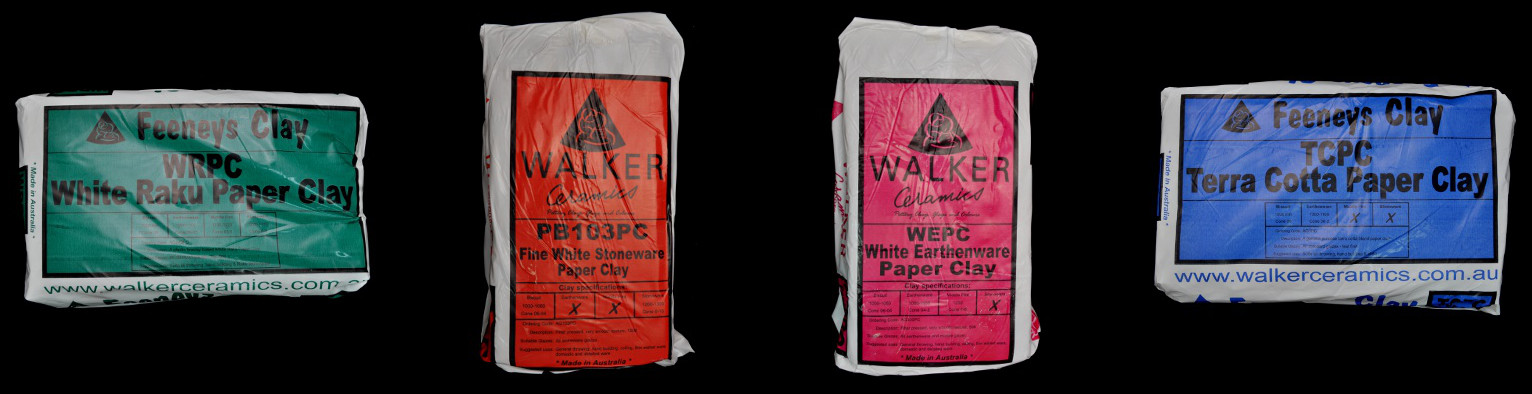

Paper clay is a specialty body made from paper pulp and clay, making it extremely plastic due to the wet mix and de-airing manufacturing process. The bisque firing temperature should be at least 1050°C. Paper clay can also be used as an air drying clay. Excellent for use in the class room.

Paper fibres added to the clay body give the clay a unique quality. As paper clay dries the physical strength of the raw clay increases and gives the potter greater flexibility in the way the clay is worked. Paper clay can be used in a wide range of hand built, thrown and moulded techniques.

There are several advantages to using paper clay that include:

- A clay product that is lighter in weight as some of the clay is substituted cellulose fibre.

- The clay wall can be thinner as the paper fibres form a strong bond resulting in a high degree of unfired physical strength.

Many people using paper clay find that it is possible to work with clay in unique ways. Some find that joining at any stage, including bone dry, is possible and that cracks can be repaired with a paper clay slip. It is recommended that you bisque fire the paper clay prior to the application of Design Colours, Cesco Underglazes and Wunder Colours. The bisque firing temperature should be at least 1050°C. Paper clay may be suitable for pit firing.

All Walker Ceramics and Feeneys Paper Clays are made using virgin cellulose paper fibre (not recycled) to give the ability to produce by any forming method. Walker Ceramics Paper Clays are filter pressed as well to minimize salts. All our paper clays can be thrown, turned, hand built and dried very easily. No special care needs to be taken in drying, biscuit or glaze firing….